Conveyor Systems

Conveyor Systems

eSort™ Conveyor Sorter

eSort Order Fulfillment of e-commerce orders for poly bags, parcels and boxes shipping and receiving sorters. 30 to 160 units / Orders per minute. Ideal for Zone Skipping.

eSort™ Quick Ship & Receive

eSort Quick – Ship, Receive & Cross Dock. Designed to handle high volume eCommerce goods to consumer, eSort can manifest, sort to carrier or allocate to workstations at 60+ units per minute.

eSort Conveyor Systems for Poly Bag – Parcel

The demand for Flexible Automated Conveyor Systems with modular, configurable components has never been greater than in today’s eCommerce driven Order fulfillment for Omnichannel Logistics. Large and small companies alike need agile, easy to configure, conveyor system solutions to deliver goods to consumers the next day.

eSort is intelligent innovative MDR conveyor for order fulfillment. eSort Integrates Pick, Pack & Ship systems with zone skipping sortation for streamline synchronized distribution. eSort is the next generation in flexible conveyor automation.

We provide order fulfillment for eCommerce / Omni-Channel logistics and distribution demands in a multitude of industries. eSort conveyor systems are engineered with standard off the shelf modular MDR components to provide flexible products and solutions:

We provide order fulfillment for eCommerce / Omni-Channel logistics and distribution demands in a multitude of industries. eSort conveyor systems are engineered with standard off the shelf modular MDR components to provide flexible products and solutions:

- Consolidate, Pack, label and Shipping

- Sortation for zone skipping

- Receiving & Manifesting

- Order fulfillment

- Returns processing

- Reverse Logistics

We provide simple solutions to complicated processes with intelligent products designed for easy set-up and rapid automation implementation. eSort provides innovation that improves your bottom line.

eSort Conveyor Systems and Solutions

eSort Conveyor systems allow for unmatched design flexibility by utilizing modular equipment that provides engineers the ability to easily modify, expand or reconfigure systems and layouts as required. Rapid automation development and deployment in days instead of several months makes eSort the most cost-effective conveyor sortation system in the material handling industry.

eSort Automated conveyor systems benefits for Omnichannel and Distribution Reverse Logistics:

eSort Technology Performance

- Z1A Sorter is a light duty, low-profile sorter handling 1 oz poly bags to 25 lb. boxes sorting at 60 units per minute.

- Z1B Sorter is a medium duty, low-profile sorter handling 1oz poly bags to 50 lb. boxes sorting at 50+ units per minute.

- G4 Sorter is the most versatile Poly bag/Box sorter in the industry. Handling/Sorting 1 oz. poly-bags and boxes up to 65 lbs., inline and co-mingled at the same time at a rate of 30 units per minute

- G4 and Z1’s can be run together, inline and also in a multi-level configuration

- eSort equipment can plug into a 110v outlet, such as on a receiving dock to sort and manifest products

- Easily expandable from 1,800 to 18,000 sort capacities per hour

- Provides the most cost-effective price per sort, from 3 to 300 sort destinations

Learn More About eSort Technology

MDR Conveyors Performance

- Our motor driven roller conveyor (MDR) provides simplified and distributed network controls that reduce engineering timelines especially during installation in the field

- Truly modular, plug in and run conveyor systems that provide a faster return on investment than comparable models

- Conveys and sorts packages other systems cannot process, from lightweight 1 oz. polybags to 65 lb. boxes

Intelligent automation from eSort conveyor will have you operational, rapidly and cost-effectively, to meet next day demands for Omnichannel and Reverse Logistics distribution. eSort modular conveyor allows for more compact configurations than other products, yielding a much higher throughput for less capital expenditure.

eSort Conveyors’ skilled and experienced automation engineers deliver exceptional solutions and designs for any application requiring automated conveyor systems. eSort provides ongoing customer service and support to ensure your success, satisfaction and expansion requirements will be according to your plan.

Learn More About MDR Conveyors

ABOT Box Cutter Performance

- Typical ROI in 6 to 8 months

- Unmatched productivity rate (cartons per hour, CPH) over comparable machines

- Up to 710 CPH for single line conveyor

- Up to 1420 CPH for dual line conveyor

Cost is typically 25% less than other manufacturers’ machines that are not as productive

Learn More About the ABOT Box Cutter

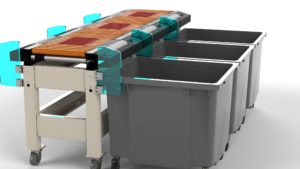

ABOT Box Opener

ABOT is the next generation in automated box cutter technology. Powered by 24v DC the innovative ABOT does NOT require: air, PLC or a control panel to operate. It easily plugs into a 120v outlet or other power source to run.

The ABOT is engineered with MDR conveyor, PGD drives and Ethernet control card technology, opening the widest range of box sizes at the highest single line rate in the material handling industry. It can be deployed on casters as a mobile unit or easily integrated into any existing or new conveyor system.

Learn More About ABOT Box Cutters

eSort Conveyor Makes the Difference

eSort Conveyor provides the essential components for versatile, innovative and flexible automation for material handling applications. eSort Conveyor is engineered for Omnichannel distribution and the agile processes that these operations demand.

eSort Conveyor and our valued industry partners provide the design engineering for applications that deliver.

eSort Conveyor Systems. Contact eSort today to learn more about our innovative next generation eSort 24v DC conveyor products & Systems.