Omni Channel order fulfillment, reverse logistics, returns processing, receiving, automated box opening and pharmacy fill

The demand for processing orders consisting of boxes, polybags, packages and envelopes with speed and accuracy has never been a more intensive requirement for companies large and small delivering goods to consumers for next day delivery. We provide adaptable solutions for a several applications including:

Quick eSort

Quick eSort – Receiving, Shipping and Cross Dock

This system was developed to handle substantial volume of eCommerce goods to consumer at shipping, cross dock and receiving / returns to manifest, sort to carrier, allocation to workstations, zone skipping or last mile sorting.

- One Sorter processes poly bags, parcels and envelopes accurately and efficiently @ 60 units per minute

- Manifest and track bags, parcels and boxes at once

- Real-time Inventory Manifest Confirmation

- Automated Scanning Receiving and Sortation of trucks

- Low capital cost and Flexible Sortation configurations

- Quick implementation (one day)

- Mobile on wheels and built for TOUGH DOCK environment

SARA

Store Automated Receiving and Allocation

This system was developed to substantially improve big box and large retail store receiving, manifesting and allocation of inventory by category.

- One Receiving Sorter Unloads 1 to 3 Trucks accurately and efficiently with less labor

- Build Aisle Friendly Pallets for Store

- Real-time Inventory Manifest Confirmation or Creation Per Truck

- Automated Scanning Receiving and Sortation of trucks

- Low capital cost and Flexible Sortation configurations

- Quick implementation (one day)

- Unloads & Processes Trucks Much Quicker

Order Fulfilment eSort Poly Bags & Boxes

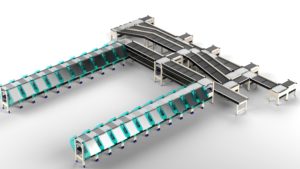

Z1A eSort / Auto Bagger System – Sortation by Carrier

- Material handling designed from the ground up for polybags, envelopes and parcels

- Next generation safe MDR technology with networked distributed controls

- Compact foot print

- Expandable sort capacity up to 2,400 orders per hour

- Engineering time and cost dramatically reduced

- Manufacturing & Install time dramatically reduced

- Software requirements dramatically reduced or eliminated

- FAT simplified and reduced

- Installed & Commissioned on-site in days

Reverse Logistics Returns Processing

Revers logistics and Returns processing involves, opening, processing and sorting product to the proper department or freight destination. The ABOT box opener is easily integrated with eSort and processing system that can be mobile or fixed. Allowing trailers of inbound product to be effectively processed at a dramatically improved rate for very little investment.

Revers logistics and Returns processing involves, opening, processing and sorting product to the proper department or freight destination. The ABOT box opener is easily integrated with eSort and processing system that can be mobile or fixed. Allowing trailers of inbound product to be effectively processed at a dramatically improved rate for very little investment.

- Receiving Sort to Gaylord (Zone Skipping)

- Receiving > Open boxes > Process/repack > Sort to Pallet or gaylord

- Complete Returns processing modules

- Flexible, reconfigurable on the fly and easily expandable

Pharmacy Fill

Processing and sorting poly bags is a difficult at best. The eSort modular MDR conveyor and sortation system allows for high speed sortation in 1/3 the space at 1/2 the price. The simplicity of eSort product has changed how Pharmacy fill operations can process prescriptions and orders with light weight poly bags.

Processing and sorting poly bags is a difficult at best. The eSort modular MDR conveyor and sortation system allows for high speed sortation in 1/3 the space at 1/2 the price. The simplicity of eSort product has changed how Pharmacy fill operations can process prescriptions and orders with light weight poly bags.

- Multiple level sort Diverts

- Low profile

- Rates from 40 to 120 per sort destination at a speed of 150 feet per minute

- Easily expandable

- Implementation & Installation schedules dramatically reduced

ABOT Box Opening

ABOT opens a variety of box sizes in line to receive or processing items at a very high rate in a very small footprint. The application for ABOT is very broad for distribution & logistics and with its’ modular design is easily added to reverse logistics and returns processing work cells.

ABOT opens a variety of box sizes in line to receive or processing items at a very high rate in a very small footprint. The application for ABOT is very broad for distribution & logistics and with its’ modular design is easily added to reverse logistics and returns processing work cells.

- Reverse logistics and Returns Centers

- Receiving at DC’s or Stores

- ASRS Multi Shuttle Replenishment

- Split Case or Repack

- Mobile and Fixed Systems